HOME > APPLICATIONS > Induction Brazing / Soldering

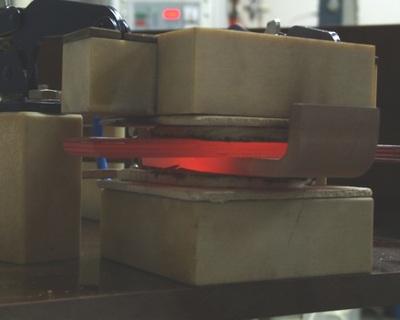

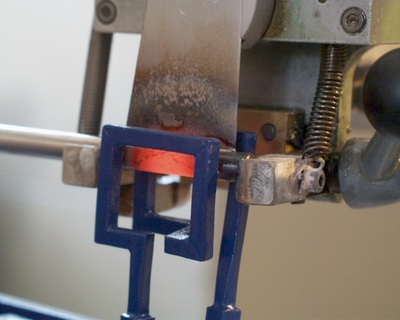

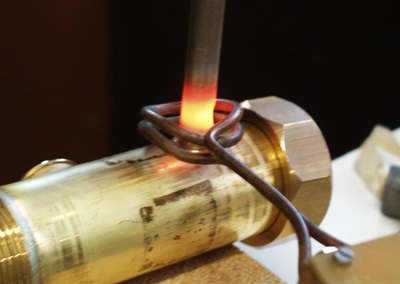

Induction Brazing / Soldering The different inductive brazing methods, such as soldering, welding, and high temperature brazing, are already industry standards. This is due to the optimized energy transfer that is inherent to inductive heating. A simple ratio can help to explain -> 1:200:1000 (furnace, flame, induction)

Induction soldering is mainly used when poor accessibility exists and a high reproducibility is required. Main advantages of induction heating: - Rapid operation - Cost effectiveness - Consistent quality - No energy costs during breaks and idle - Non-abrasive work pieces Examples of specific applications: Electronics: Wires, transformers, motors, switch contacts, RF connectors, copper profiles, copper pipes, and pipe bends. Automobile: Transmissions, climate control, ignition coils, and short-circuit rings. Tool-making: Core drills, saw blades, and precision milling tools. Household appliances: Water valves, heating elements, and immersion heaters. |

|