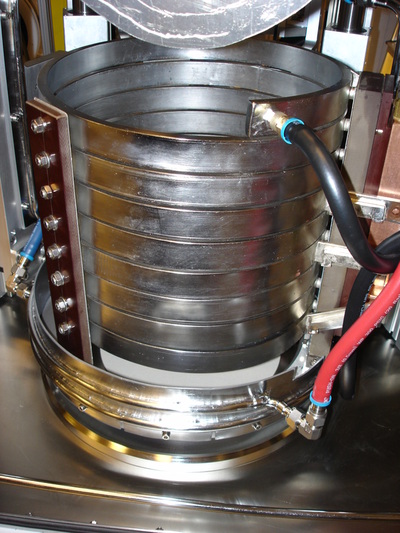

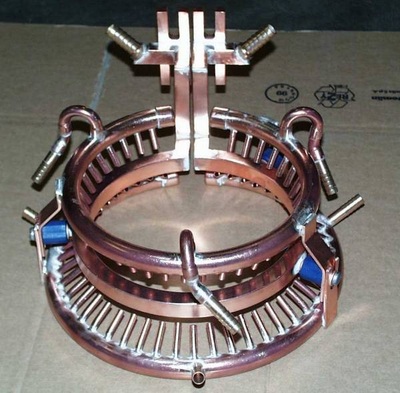

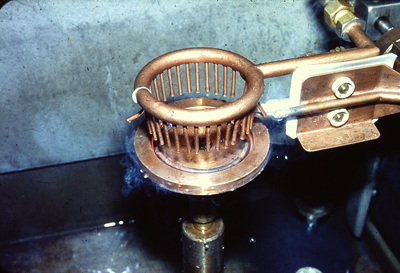

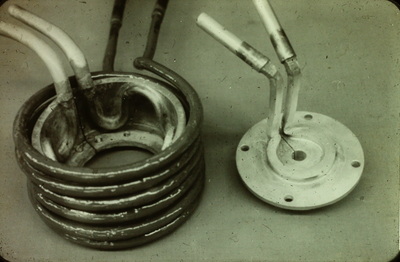

Induction Coil Services for 1 to 600kW SystemsSpecial coils are required for each inductive heating process, such as: tempering, soldering, melting, and annealing. The inductive coil is commonly referred to as a: heating loop, heating coil, heat conductors, work coil, and annealing loop. The inductor transmits the power supplied by the generator to the work piece by means of the alternating magnetic field.

Inadequate construction or improper dimensioning of an inductor leads to poor heating results. The skill and ability of the design engineer are particularly challenged in the design process. Often laboratory tests are required to fine tune and finalize the design. The shapes of inductors are very diverse since they must be adapted to the shape of the work pieces to be manufactured. There are single and multi-turn, round, square, and such a hairpin shape, which is very complicated and requires absolute precision. During construction the following points should be noted:

The shape of an inductor depends on the required heating zone. This is primarily influenced by the shape of the work-piece. Within reason, the shape of an inductor can be determined in advance. Inductors with more complex designs often have unexpected heating zones that arise from the interaction of magnetic fields from various curves, bends, etc… when the inductor only templates hard shape of the work-piece follows. Here the practice and skill of the developer is called upon, and keeps the development process swift and accurate. |